PEF Technologies is developing an innovative technology that can preserve liquids at lower temperatures, without loss of taste, color and nutritional value. The technique uses up to 50% less energy than the current method of pasteurisation. Energiefonds Overijssel, Oost NL (from Innovatiefonds Overijssel) and Icos Capital are jointly investing €1.5 million in the further development of the technology and market introduction of PEF Technologies.

Pasteurisation prevent liquids such as dairy products and fruit juices from spoiling as quickly. To accomplish this, the liquids must be briefly heated to a high temperature, which kills harmful bacteria. Unfortunately, as heat is applied, the taste changes and the product loses nutritional value. This heating is also costly and uses large amounts of energy. These challenges leave many food producers looking for alternatives.

NanoPEF

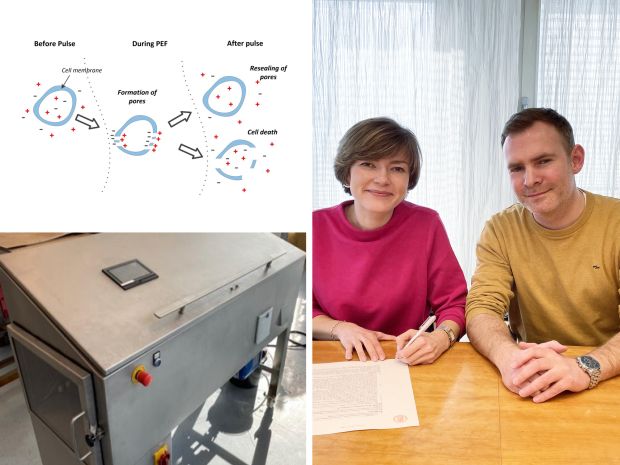

PEF Technologies has found an alternative to this in the form of “nano-PEF” (nanosecond Pulsed Electric Fields). With that solution, one-month-old milk is still as delicious and healthy as the day the cow was milked. Yulia Mitko, Director of Operations at PEF Technologies explains: “We have developed a machine that can send an electric pulse of very high intensity for an extremely short duration – nanoseconds – through products. With this we kill the bacteria in milk, for example. In the process, the processing temperature does not exceed 65 degrees.” The technology is unique because of the length of the pulse, just nanoseconds. PEF Technologies is the first company to use nanoPEF for its technology.

First results and future

With the investment, PEF intends to further develop its technology. This will require further construction and expansion of the organisation. Mitko: “In recent years, we have conducted many positive tests with food producers from different sectors. However, our goal is the most complicated product: milk. Besides pasteurisation, there are several other alternative preservation technologies, but none are fully suitable for milk processing without compromising the functionality of valuable proteins. The first tests of nanoPEF-treated milk were promising; we are therefore now validating our technology at a major dairy producer in the Netherlands.” The investment will achieve a social return of up to 50% savings in energy to be used and create ± 15 full-time jobs in the local province.

€1.5 million investment

In the summer of 2022, Energiefonds Overijssel, Icos Capital and Oost NL first invested in PEF Technologies. This has now been followed up with this investment round. Nityen Lal from Icos Capital says: “The technology behind PEF is very exciting and undoubtedly a solution to contribute to sustainable food systems. We look forward to working together with the PEF Technologies team and they are fully committed to making nanoPEF the next pasteurisation standard, resulting in food with a better taste, better quality and in a better environment.”